Special Alloys

Tubing

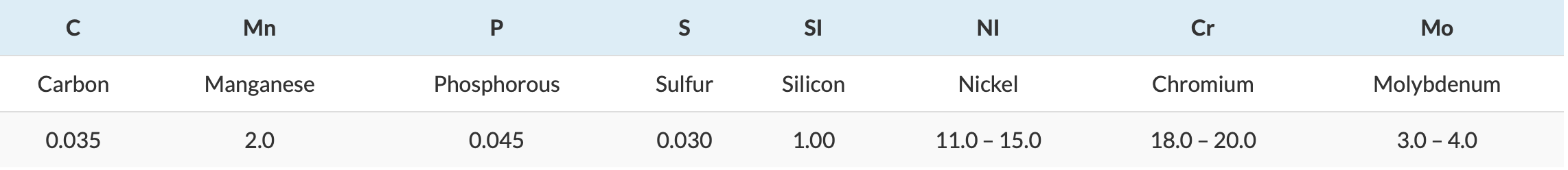

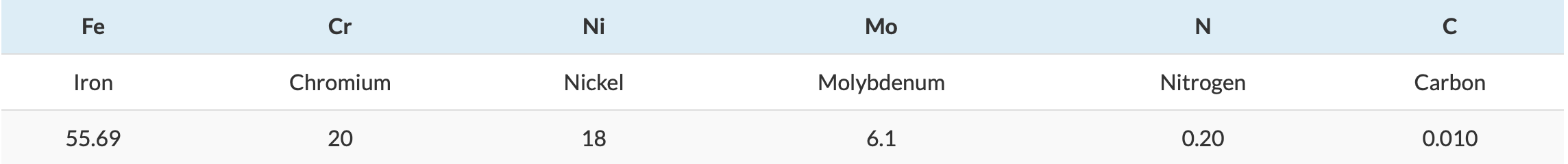

317L Stainless Steel

(UNS S31703)

Similar in composition to 316L and 304L, alloy 317L is an austenitic molybdenum-chromium-nickel stainless alloy, 317L has higher Creep, stress-to-rupture, and tensile strength than its 316L and 304L counterparts and due to the higher moly content, 317L provides enhanced resistance to pitting and stress corrosion cracking particularly in chloride or halide rich environments. This is a great solution to demanding applications such as those that can be found offshore and in chemical processing plants.

PRODUCTION SPECIFICATIONS

ASME SA213/ASTM A213/NACE MRO175

Typical Applications

Chemical and Petro-Chemical

Pulp & Paper

Food Processing

Offshore Oil and Gas Production

Textile Equipment

Tubing

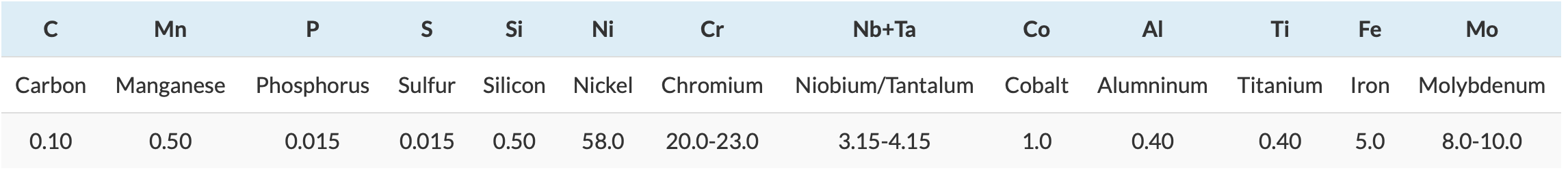

Alloy 625 Tubing

(UNS NO6625)

Alloy 625 is an austenitic nickel alloy resistant to crevice corrosion and oxidation, specifically under a wide range of temperatures from cryogenic to 1800°E . This makes the product well suited for nuclear and aerospace applications. The main feature of alloy 625 is the addition of niobium which increases the strength of the tubing without heat treating.

PRODUCTION SPECIFICATIONS

ASME SB444/ASTM B444/NACE MRO175

ALLOY 625 (UNS NO6625) CHEMICAL COMPOSITION % (MAX.)

Typical Applications

Nuclear

Offshore Oil/Gas Production

Aerospace

Heat Exchangers

Chemical Processing

Tubing

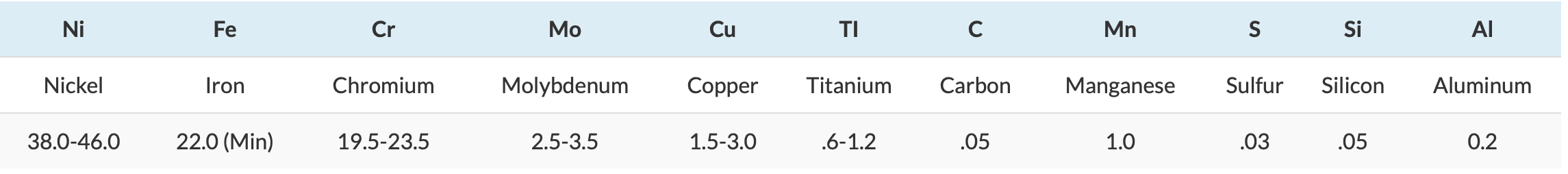

Alloy 825

(UNS NO8825)

825 is an austenitic nickel-iron-chromium alloy also defined by Alloy additions of molybdenum, copper, and titanium. It was developed to provide exceptional resistance to numerous oxidizing and reducing corrosive environments. With a nickel content range between 38-46%, this grade exhibits pronounced resistance to stress corrosion cracking (SCC) induced by chlorides and alkalis. The chromium and molybdenum content provides good pitting resistance in all environments except strongly oxidizing chloride solutions. Utilized as an effective material in a wide variety of process environments, Alloy 825 maintains good mechanical properties from cryogenic temperatures to 1,000 ° E

PRODUCTION SPECIFICATIONS

ASTM B163/ASME SB163, ASTM B829, NACE MRO175

ALLOY 825 (UNS NO8825) CHEMICAL COMPOSITION % (MAX.)

Typical Applications

Acid Production

Oil and Gas Production

Pickling Operations

Radioactive Waste Handling

Sulphuric and Phosphoric Acid

Sour Gas and Oil Wells

Heating Coils and Tanks

Food Processing Equipment

Tubing

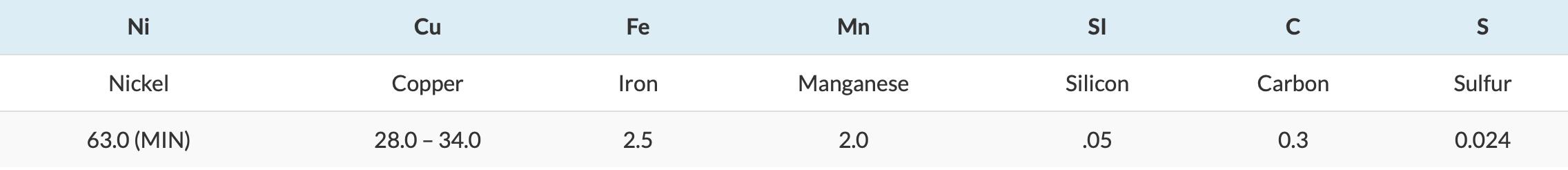

Alloy 400 Tubing

(UNS NO4400)

This nickel-copper chemistry features a high intensity single-phase solid solution metallurgical structure. Alloy 400 has greater corrosion resistance than nickel under reducing conditions and is more resistant than copper under oxidizing conditions. This grade has been widely used in applications requiring strong resistance to corrosive environments featuring acids, alkalies and high temperature steam. It is all but immune to the stress corrosion cracking (SCC) induced by chlorides and most freshwater conditions. A very tough material (as measured by impact testing) Alloy 400 has excellent mechanical properties in sub-zero conditions. It does not undergo a ductile-to-brittle transformation even when cooled to the temperature of liquid hydrogen. On the opposite side of the temperature range, Alloy 400 performs well in temperatures up to 1000° F.

PRODUCTION SPECIFICATIONS

ASTM B163 /ASME SB163, ASTM B165, NACE MRO175

ALLOY 400 (UNS NO4400) CHEMICAL COMPOSITION % (MAX.)

Typical Applications

Sulfuric Acid Environments

Sour Gas Well Environs

Pollution Control

Sea Water

Organic/Inorganic Chlorides

Pulp & Paper Production

Sulfur Compounds in Flue Gas

Tubing

Alloy C276

(UNS N10276)

6 Mo (UNS S31254) is a super austenitic stainless steel with a high level of molybdenum and nitrogen, providing high resistance to pitting and crevice corrosion as well as high strength compared with conventional austenitic stainless steels such as 316L. The alloy can provide excellent resistance to stress corrosion cracking allowing tube cold forming and may be used without the necessity to re-anneal at testing up to 120°C.

PRODUCTION SPECIFICATIONS

ASTM A213 ASTM A269 ASTM A312

Typical Applications

Seawater handling systems

Paper and pulp

Offshore Oil/Gas Production

Desalination plant equipment

Flue gas desulphurisation units in power plants

Tubing

Alloy 6Mo UNS

(UNS S31254)

This nickel-copper chemistry features a high intensity single-phase solid solution metallurgical structure. Alloy 400 has greater corrosion resistance than nickel under reducing conditions and is more resistant than copper under oxidizing conditions. This grade has been widely used in applications requiring strong resistance to corrosive environments featuring acids, alkalies and high temperature steam. It is all but immune to the stress corrosion cracking (SCC) induced by chlorides and most freshwater conditions. A very tough material (as measured by impact testing) Alloy 400 has excellent mechanical properties in sub-zero conditions. It does not undergo a ductile-to-brittle transformation even when cooled to the temperature of liquid hydrogen. On the opposite side of the temperature range, Alloy 400 performs well in temperatures up to 1000° F.

PRODUCTION SPECIFICATIONS

ASTM B163 /ASME SB163, ASTM B165, NACE MRO175

ALLOY 400 (UNS NO4400) CHEMICAL COMPOSITION % (MAX.)

Typical Applications

Sulfuric Acid Environments

Sour Gas Well Environs

Pollution Control

Sea Water

Organic/Inorganic Chlorides

Pulp & Paper Production

Sulfur Compounds in Flue Gas

Tubing

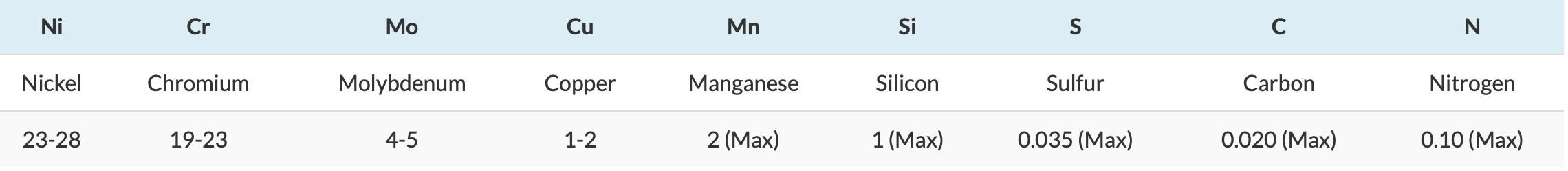

Alloy 904L UNS

(UNS N08904)

UNS NO8904, commonly known as 904L, is a low carbon high alloy austenitic stainless steel which is widely used in applications where the corrosion properties of AISI 316L and AISI 317L are not adequate.

Alloy 904L has a high resistance to pitting in chloride solutions, a high resistance to both crevice and stress corrosion cracking. This grade performs better than other austenitic stainless steels due to the higher alloying of nickel and molybdenum. Alloy 904L is particularly useful in control and instrumentation tubing applications where 316 and 317L are not suitable.

PRODUCTION SPECIFICATIONS

UNS N08904 ASTM A213 ASTM A269 ASTM A312